Uncategorized

Authorized, Competent, Qualified Roles & Responsibilities in Rope Access

A key requirement in the ANSI Fall Protection Code is that the employer is required to ensure competence of designated persons. This philosophy carries over to the ANSI Z459.1 standard on rope access.

Rope Access is regulated as a part of fall protection under OSHA’s 1910 General Industry rules, specifically in Subpart D and I. Rope access is standardized as part of the ANSI Z359 Fall Protection code in the document identified as American National Standard Z459.1 SAFETY REQUIREMENTS FOR ROPE ACCESS SYSTEMS.

We are going to be talking in future episodes about some of the specific requirements that apply to rope access in both these groups of documents, but first I’d like to address roles and responsibilities of personnel. In previous posts I have mentioned the responsibilities of Qualified Persons, and I’ve had some questions about whether a Qualified Person and a Competent Person are the same thing, and what that means, so let’s sort that out first.

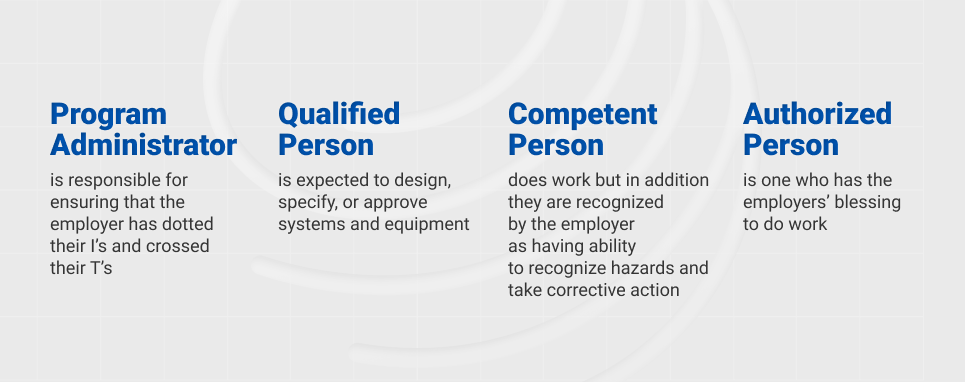

There are typically four recognized roles in any Fall Protection program. These include:

- Program Administrator

- Qualified Person

- Competent Person

- Authorized Person

The ANSI Z359.2 standard for employers who are developing a Comprehensive Managed Fall Protection Program does a really good job of diving into these roles and responsibilities in greater detail, but in short we can summarize by saying that

- The authorized person is one who has the employers’ blessing to do work

- The competent person also does work but in addition they are recognized by the employer as having ability to recognize hazards and take corrective action.

- The qualified person is expected to design, specify, or approve systems and equipment, and

- The program administrator is responsible for ensuring that the employer has dotted their I’s and crossed their T’s.

While one individual might actually be assigned multiples of these roles by an employer, the qualified person and program administrator are often not field practitioners.

That’s how it has worked in fall protection for decades.

The ANSI Z459.1 standard on rope access pretty much emulates that pattern, but of course at all levels these individuals are expected to have rope-access specific experience – not just experience in fall protection.

This is particularly important when it comes to the concept of the Qualified Person. This is the individual expected to specify, design, and/or approve systems that workers will be using. As is the case in all Fall Protection, to be considered a Qualified Person an individual must possess a professional certificate and extensive knowledge, training and experience that is relevant to fall protection and rescue. Taking that a step further, under the ANSI Z459.1 guidance the Qualified Person must also possess a professional certificate specific to rope access, as well as extensive knowledge, training and experience specifically in rope access, fall protection and rescue.

Although qualified persons in other areas of fall protection may not have extensive knowledge of rope access, it is essential that the Rope Access Qualified person have a depth and breadth of knowledge not only of rope access and regulatory requirements, but also of other fall protection methods and regulatory requirements as they pertain to the jurisdiction in which they are working.

The responsibilities of a Rope Access Qualified person include the verification of the appropriateness of the access method to the worksite or location, design/approval of the system to be used, specification of skill level requirements for each employee, specification of appropriate management practices, and approval of the rescue plan. The Rope Access Qualified Person is not necessarily expected to perform as a field technician.

As far as the designation of a COMPETENT ROPE ACCESS TECHNICIAN, this term “competent” is used consistently with other OSHA and ANSI language in that the Competent Technician is one who is capable of recognizing hazards and who has the employers authority to take prompt corrective action. To do this, they must be trained and experienced enough to monitor, evaluate, and address existing and potential fall hazards. On a practical level, typically this means that they are named by the employer in some sort of supervisory capacity.

You may note that in the case of Rope Access we are calling this person a Competent Technician, rather than a Competent Person. That’s because this individual IS expected to be capable of working on rope, in the field, as well as providing immediate supervision, implementation and monitoring of work – and of course they will have the employer’s authority to take prompt corrective action.

Likewise, the term AUTHORIZED Technician is also used in a manner consistent with other ANSI and OSHA standards in that this are defined as one who has been authorized, or given permission, by the employer to perform a given task. The Authorized Technician must be trained sufficiently to operate within the scope of their duties, but generally does not have supervisory authority and is not expected to take corrective action. For example, if they see something questionable in the rigging, their own safety is their first priority; rather than trying to fix the rigging or revise it, they should report the situation to a Competent Technician or Program Administrator.

The responsibilities of the Authorized Technician begin and end with whatever rope access or related tasks they are assigned by the employer to perform. They are responsible only for working within the context of their assigned duties.

Some people have asked whether these roles equate in any way with any existing trade association training schemes or levels of rope access certification. The answer to that question is “not necessarily.” The Authorized-Competent-Qualified concept is something that has been in OSHA and ANSI vernacular for decades, but the levels found in certifications programs appear to have more to do with different types of rope-specific skills than with evaluation of design or supervisory capabilities.

Further to that, it is important to recognize that ONLY THE EMPLOYER can designate whether an employee is Authorized, Competent, or Qualified relative to a given job. This designation is not just about having the appropriate knowledge or training, more importantly it is about what level of responsibility and authority an employer delegates to them within the context of a specific assignment.

Just because a person has received, for example, Competent Technician Training, this does not necessarily MAKE them a Competent Technician; having appropriate knowledge is just a prerequisite. It is only upon being recognized as a Competent Technician and being assigned by the employer to function in the role of a Competent Technician that the designation is relevant.

Likewise, it is up to the employer what knowledge and skills are necessary for each classification in their particular work situation, and this often varies from job to job. This goes beyond just rope skills and includes knowledge relevant to the worksite, the task or trade being performed, the employer’s work practices, and relevant regulatory requirements.

So, this begs the question: Do Authorized, Competent, and/or Qualified persons in rope access need to be certified by a relevant trade organization or certification scheme?

We will delve into that further in a future post – but just to whet your appetite, consider: Certification by a recognized entity is arguably one of the BEST ways to verify what level of rope-specific skills a rope access technician has!

That said, most of the certification schemes are relevant for working all over the world, so when it comes to training and certifications the knowledge that a certified technician has received may or may not be relevant to a given jurisdictional regulation.

In other words, just because someone is certified as a rope access technician by one of these organizations, that does not necessarily mean that they have been trained in accordance with OSHA requirements as they pertain to Rope Access use in the United States. It is up to the employer to ensure that technicians are using appropriate equipment and methods to maintain compliance under the jurisdiction in which they are employed.

Well, that’s a lot to digest, I know. We’ll stop here for now and pick up later with additional questions. If you would like to submit questions please feel free to do so in the COMMENTS box here, and we will do our best to address them.

My name is Loui McCurley, and I appreciate your joining me today. Climb high, and stay safe.

0 comment