Standards and Compliance

NFPA Delays Implementation Requirements for NFPA 2500 (1983)

Earlier this year, PMI released a blog post talking about NFPA 2500 – what it is, what it might mean to you, and how to use it. If you want to review that information, you can find it on our website, at www.pmirope.com.

One of the things we talked about in that post was the release date of the NFPA 2500 document and just how long it might be before you actually see gear being marked to the new standard.

Today I am here to let you know about an important update to NFPA 2500; but if you haven’t reviewed the original post you might want to check that out too.

There are more than 30 people who are part of the NFPA Special Operations Protective Clothing and Equipment Committee that oversees NFPA 2500. The people who sit on this committee are not just manufacturers, but also represent test labs, fire departments, training companies, rescue teams, and more. NFPA standards development processes are compliant with ANSI protocol, and prevent any one interest group from becoming a majority. This may come as a surprise to some who might believe that standards are written by and for manufacturers themselves.

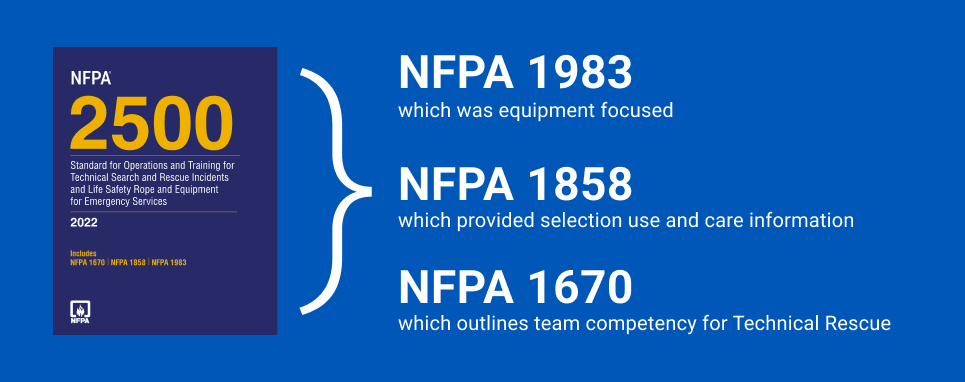

The NFPA 2500 standard combines what used to be three separate documents… NFPA 1983 (which was equipment focused); NFPA 1858 (which provided selection use and care information) and NFPA 1670 (which outlines team competency for Technical Rescue.) Now, the substance of all three of those documents is contained in just one standard.

This is important, because if you are a fire department you might be accustomed to looking for markings on your equipment that say NFPA 1983, along with some year-reference.

But pretty soon the equipment you’re used to seeing with these markings is going to be marked NFPA 2500, with (1983) in parenthesis, and then the effective year – in this case, 2022. This standard is updated once every five years, so it will be awhile before that effective date is changed again.

Here’s where the new information comes in. In our previous post, we talked about the fact that the standard was released in 2021, with a 2022 effective date, and we talked about how manufacturers were given a deadline of September 2022 to get all their gear re-tested and re-marked to the new standard.

However, earlier this year NFPA released a Tentative Interim Amendment (TIA), extending that deadline for an additional six months, due to administrative delays.

As a result of this change, marking to the new NFPA 2500 (1983) 2022 standard, which was released all the way back in 2021, is actually not required until early 2023!

Please keep in mind that there is no limit on when you have to stop buying or using equipment that is marked to older versions of the NFPA 1983 standard; in fact, most of the provisions and requirements for equipment testing have not really changed. There are no NFPA requirements to stop using certain equipment, there are no particular hazards or concerns associated with continuing to use gear marked to a previous version of the NFPA standards. Their only rule is that as of Spring 2023 MANUFACTURERS have to stop selling equipment marked to the 2017 edition of 1983.

Stay vertical, and keep on climbing with PMI!

Jonathan Isenberg

I am an Assistant Chief from Williamsburg Volunteer Fire Company from Williamsburg, Pa. I noticed with the recent increase in g-rated 7/16 rope that it now seems all the big companies are producing it. I was hoping maybe you could answer a few questions for me regarding 7/16 G-rated rope.

Do you see a lot of Fire Company’s now purchasing this over 1/2 rope? Do you see 1/2” rope being phased out over the next 5-10 years? My fire company will possibly be coming into funding which would give the chance to switch over to 7/16 and get away from 1/2 rope. I am looking for this information so we can make the correct decisions moving forward regarding equipment purchases.

I do like how 7/16 is so much lighter and cheaper while still holding all the same properties as 1/2 rope such as strength, abrasion resistance and stretch. Are you seeing any disadvantages of 7/16 over 1/2 rope?

Thanks for your input.

Jon Isenberg

LOUI MCCURLEY

Hi Jon – Great question, thanks for reaching out! We published an answer as a special post “NFPA 11mm G-Rope – Is It a Gimmick”

With the advent of G rated 11mm rope many departments have begun to move to the smaller diameters.There are a lot of advantages, including a wider range of auxiliary equipment that works with this diameter, harmonization with professional rope access systems and methods being used in the field, and – as you so aptly point out – lighter weight and less cost.However, there are still many departments who are opting to take things a bit more slowly. This can be a very costly process, because you must also replace all critical life safety components that are diameter dependent at the same time (bollard type descenders and rope grabs.) However, adjustable friction devices such as the brake rack are more forgiving, and the same size device can be used on both diameters of rope.As far as performance properties… 11mm (and lower) diameter ropes have been permitted in context of NFPA for over a decade, and have been used in mountain rescue, cave rescue, rope access, and industry for even longer. The durability, abrasion resistance, flexibility, and stretch of an 11mm rope are all engineered features, just as they are in a 12.5mm. I can show you 11mm ropes that are more durable than a 12.5mm rope, and vice-versa, just depends on materials and construction. For greater durability, choose a thicker sheath (ie, fewer carriers) and stiffer (more tightly woven) kernmantle rope, for greater flexibility choose a thinner sheath and more loosely woven rope. Elongation is measured as a ratio against MBS, so you should find these aspects comparable.

I hope this answers your questions… feel free to reach back out if we can offer further clarification or additional perspectives.