Care and Maintenance

Rope bags

What it is, is in the name – they are bags for rope. But what it does, is sooooo much more. The rope bag is, arguably, the hardest working piece of gear there is. It protects our rope, our most foundational yet vulnerable piece of equipment, and in doing so it protects our very lives. From the moment it’s put into service it is doing what it does during, in between, and especially on the way to every project of it’s lifespan.

Think about it: You suddenly find yourself on your way perform a last minute, urgent, one day, visual inspection job on a roller coaster at an amusement park on the other side of the country. With no time to ship gear in advance, you’ll have to fly with all your equipment – including your rope (good thing the client is picking up the extra baggage fees).

Are you going to place those coils of naked rope on the scale at check in counter? Or endure the strange looks and stupid jokes from fellow passengers because your carry-on is a coil of 100m rope?

In this moment, you begin to understand just how wise a choice you made in popping for the expense of a rope bag.

Aside from keeping our precious safe from the hands of under-paid baggage handlers, over-zealous TSA agents, and the unknown horrors found in the belly of airport baggage systems, rope bags protect our ropes from the harsh environments to which we so cruelly subject them while in storage, and on a project.

Especially on large projects, days (if not weeks) can be spent simply rigging ropes and gear to make access to the actual work location. A single project can involve hundreds of individual ropes of varying lengths and specifications, adding up to several miles of total rope necessary to perform whatever work awaits. With a burst of static the radio blares out a request from the lead technician for a specific rope. With so many pieces of rope in the cache, thank heavens for the clearly discernable labels on the outsides of the bags! Even the rookie ground guy is able to find the right one!

As the valuable load is hauled into place, secure in it’s protective bag, you can put to bed any fears of the load (ropes) from getting snagged on all those unseen sharp edges and pinch points along the way.

Working double time

Rope bags are equally as vital when the contained ropes are in service, from outset to demobilization.

Rigging is a demanding task. The 100% focus required when a tech is moving across a span, setting lines, and rigging systems is quite enough to be thinking of. The last thing one would want to deal with is a tangled, knotted rope while standing on a beam barely the width of their boot while perched hundreds of feet above the ground.

Even for a technician on-rope the bag can be vital to safety. Work at height can be windy – which, in itself, is not a great hazard. However, when work is not managed effectively with respect to the wind, the hazard can be enormous. Ask anyone who has ever been thrust as a fleshy wrecking ball into a steel wind turbine tower; these are some of the most terrifying moments in a lifetime. In circumstances such as these, often the only option is to go straight down, and at an expedited pace. When multiple ropes are left free hanging, nature can tie knots you’ve never heard of.

Another serious safety hazard that can be created by loose hanging ropes comes from falling debris. A couple of common industries particularly susceptible to such would be rock scaling and smokestack work. It is probably safe to assume that a 600lb rock or chunk of caustic chemical found caked to walls of a stack would have a very adverse effect should it snag on the tail of a rope coming out of a workers descender as it falls down below.

When it comes to rescue, rope bags are also vital. Not just in the ease of getting the ropes up to where they are needed, but also for the ability of the rescuer to be able to negotiate an appropriate route back down with the patient. In many environments, such as the telecom world, straight down isn’t an option due to equipment and obstructions mounted to the towers.

What to look for in a rope bag

What comprises the best all-around rope bag is in the eye of the beholder (unless it’s one that a percentage of each sale goes directly into my personal bank account). A good rule of them when purchasing a rope bag is to make sure that its features meet the specific needs of what, where, and how the rope is going to be used. Some of us may have started out using typical backpacks bought from thrift stores as rope bags. Sure they worked, just not very well. Over the many years and many industries, time and experience provide personal insight into what to look for in a rope bag.

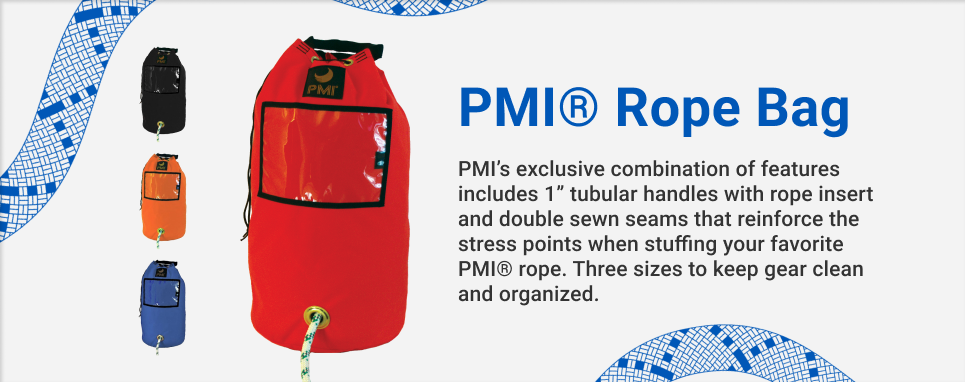

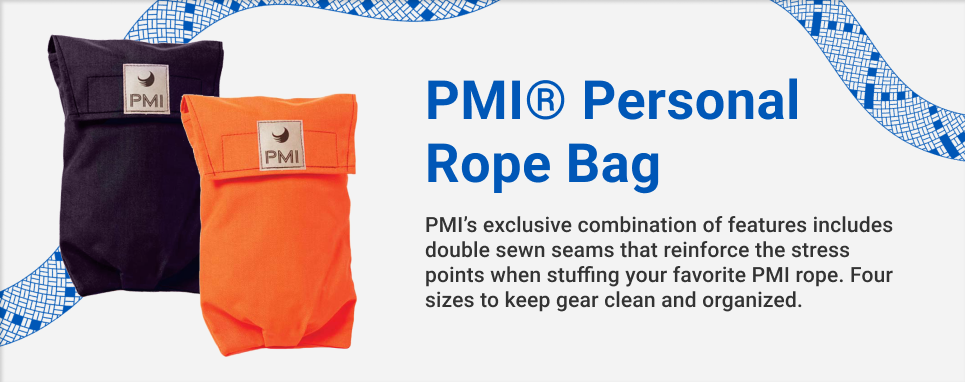

First and foremost, is it tough enough for the environment? Most nylon bags can handle some abuse. However, baggage handlers will administer that amount. A bag constructed of heavy packcloth, PVC or ballistic cloth will hold up much better than light weight nylon – much stronger and tear resistant. Durability, of course, must be balanced against weight and co-efficient of friction. In my initial work on wind turbines my thought was simple nylon for sliding bags over the side of a smooth fiberglass nacelle. However, I quickly learned that bolt heads and threads are very sharp, and that even ‘smooth fiberglass’ can chafe material. Being ‘waterproof’ doesn’t hurt either. PMI rope bags are constructed of rugged, heavy-duty coated canvas that holds up to even the harshest of abrasion, and is sturdy enough to hold some shape even when empty. Some PMI bags offer a double-layer bottom for even greater protection.

Next, look at the external handles/straps. Size, stitching and arrangement are all important factors. Stitching is especially critical if you’re planning on hoisting your rope bag – face it, 200 meters of rope is a bit too much weight to climb with. A substantial attachment point to hang that heavy load from while on rope will prevent misery in the field. Things like shoulder straps are crucial if the bag will need to be carried for any appreciable distance or across uneven terrain. Not just any shoulder-straps, either. Make sure they’re ergonomic, adjustable, and comfortable to wear. Plain two-inch webbing will feel an awful lot like a commando-wire cable saw cutting into your shoulders after the first fifty-feet. All PMI rope bags have firmly mounted handles at the top, and those handles aren’t just a strip of webbing. No, they’re rounded out to a diameter that spreads the load more comfortably across your hand rather than digging into your fingers. PMI rope bags with shoulder straps are actually called ‘rope packs’ and these feature a curved, lightly padded, adjustable carrying system that optimizes comfort and weight, similar to backpack straps.

Another critical feature to consider is how you will get the rope into – and out of – the bag. Stuffing a floppy rope bag is like trying to push a rope up a staircase. A top-load bag with substantial enough bag material to hold at least a bit of shape as you hold it at the top with one hand, and stuff with the other, is ideal. Deploying rope from a top-load bag is also an optimum situation; PMI’s draw string closure provides just enough umph to keep the rope in place without adding a lot of complexity. While recreational climbers tend to lean towards bags that unfold into a tarp, these can be more trouble than they’re worth in an industrial environment.

Something people don’t always think about is what to do with the “tail end” of the rope – the end that stuffs down into the bag first. An advantage of rope bags is that they can keep rope from tangling – but if the end of the rope that goes into the bag first isn’t secured, whatever natural wiggling and shifting that occurs in storage and carrying can cause that end to snake around, twisting, tangling, and creating all sorts of knots. Some rope bags have a grommet in the bottom through which the rope is passed and knotted before stuffing the bag; the downside of this is that there’s now a knot under your bag, preventing it from standing up straight. PMI bags address this issue by putting the grommet in front, just under the clear labeling pocket – creating something of a “belly-button” effect (it’s an outie.)

Oh, right… the clear labeling pocket! PMI’s clear pocket is made of a durable clear plastic, large enough for a very big label, product instructions, or even a full-size rope-inspection card. There’s also a hook-and-loop closure to keep all that stuff from falling out, with a little pull tab to make it easy to open when needed.

Finally, consider gear loops and pockets. Some folks like them, some folks don’t… but if you’re going to opt for pockets, at least make sure they’re big enough to hold a reasonable amount of gear. If you opt for pockets, you’ll probably also want shoulder straps (consider the weight!) In this case, be sure the pockets are in a balanced position to keep the weight centered while you are carrying the bag on your back. PMI rope-packs feature bellowed pockets that tuck down when not in use, but expand when space is needed. They also feature side release buckle closures, and those super-snazzy pack-straps for carrying on your shoulders.

0 comment